Elevating Construction Scheduling with Digital Twin Technology

Elevate construction scheduling with digital twin technology. Discover how this innovative approach enhances project management, improves accuracy, and streamlines workflows for more efficient construction processes.

Construction hugely depends on seamless project management and solid coordination between all its aspects, from design, building, suppliers, and even compliance regulations. Construction scheduling is the key to maintaining this coordination to ensure business productivity and meeting project deadlines. However, construction is a tricky arena, with multiple factors like weather, engineering, and design discrepancies and poor project management acting as hindrances in construction projects. In a survey conducted, around 72% of contractors reported facing various challenges in meeting construction schedules. These challenges, if remain unaddressed in construction, directly affect project outcomes and can cause major fluctuations in the budget. Consequently, if the actual cost is not aligned with the expected cost, construction projects may face major losses.

Technology has been paving the way in the construction sector, to introduce cost and time efficiency into projects, and has been enabling project managers and stakeholders to overcome the usual challenges, that would negatively impact construction schedules. According to a report by KPMG, around 50% of firms plan to continue investing in technologies that positively impact their project deliveries.

In this blog, we will focus on how using cutting-edge technologies like digital twins will improve efficiency in construction schedules and enhance construction productivity.

What are Digital Twins?

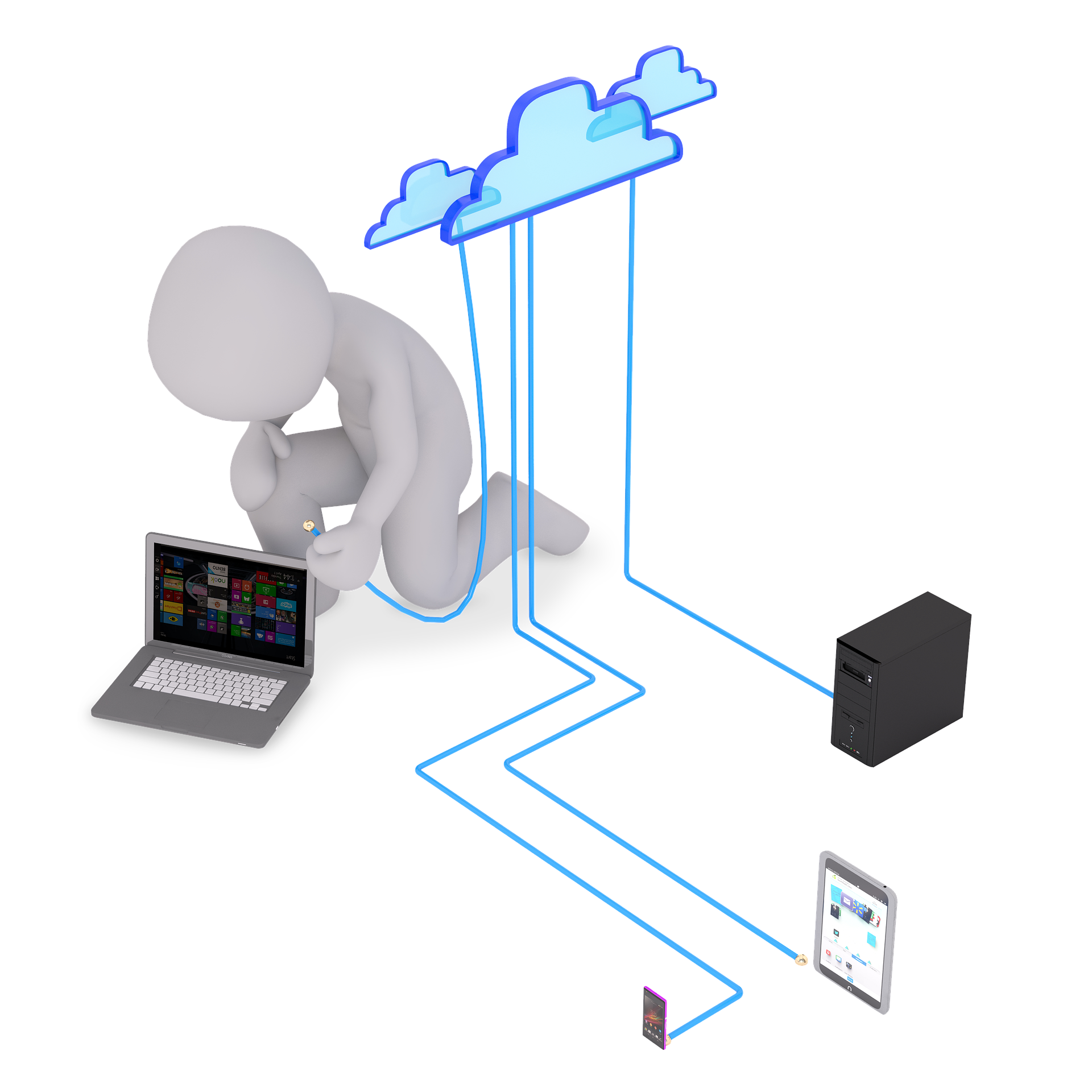

As a virtual representation of a real-world physical object or even an environment, digital twin technology is used to replicate real-world processes, like constructing a bridge, in a digital setting. Data from the real world, procured through sensors, aerial drone photography, and temperature machines, is enhanced by artificial intelligence, software analytics, and the Internet of Things (IoT) to create digital twins of real-world environments.

In a construction setting, a digital twin is an exact replica of a construction project, be it building, a highway or even a residential block. Digital twins are also called data twins or even virtual models, which enable stakeholders to access data through a single source of truth.

Why are Digital Twins Used in Construction?

Technology is incorporated with the sole aim of enhancing processes and amplifying outcomes. Be it enhancing data visibility or processing it intelligently to drive insights, technology in the construction sector has caused a seismic shift in the way projects were handled traditionally.

Digital twin technology in the construction sector has been proven to be a transformative force. It has revolutionized construction by expediting data-driven efficiency and collaboration and provides benefits that are multi-faceted.

The primary objective of incorporating digital twin technology in construction is to:

Enable project managers to monitor project progress.

Enable managers to predict outcomes.

Enable engineers to detect issues beforehand.

Enable contractors to optimize resources in a timely and cost-effective way.

Enable architects to optimize spaces in the most efficient way.

The technology, by generating a virtual replica of the physical construction site, empowers stakeholders in gaining a comprehensive understanding of the project and the intricacies and risks associated with it. This ability to monitor a project in real-time also enables project managers and stakeholders to anticipate and forecast issues and collaborate on them to proactively solve them. Its cloud-based foundation allows the team to collaborate on it from anywhere. The result is enhanced accuracy in monitoring project variables, with minimized delays and misunderstandings.

How Does the Digital Twin Technology Elevate Construction Scheduling?

Construction scheduling is a critical aspect of construction project management as it determines the proper order of activities that make up the construction process. Specific time and budget are allotted to each of these activities and the baseline schedule needs to be followed so that project success is ascertained. Let us explore how digital twin technology is used to elevate each component of a construction schedule.

Digital Visualization for Task Sequencing: A visual representation of the project can be employed by project managers and construction schedulers to identify task sequences and dependencies.

Simulation Analysis for Duration Estimation: This can be incorporated by project managers or construction schedulers in visualizing different scenarios via simulations so that their impact can be analyzed. This can be used for accurately identifying task durations while considering different variables.

Simulation-Optimization Approach for Resource Allocation: This approach incorporates optimization algorithms to analyze the possible utilization of resources. Simulation of resource allocation scenarios can be done to extract the most efficient allocation of resources like manpower, equipment, and materials.

Scenario Simulations for Contingency Planning: A contingency plan can be incorporated into the digital twin models to enable project managers to foresee any possible challenges or risks. Simulations for various scenarios can be used to empower project teams to take proactive measures and commit to a seamless contingency plan.

Real-time Monitoring for Critical Path Analysis: Monitoring the project’s progress through real-time data monitoring in the digital twin model can aid project managers and scheduling managers in identifying critical tasks and prioritizing activities that have a greater capability to influence the project timelines, in an efficient manner.

The benefits of incorporating digital twin technology into construction project scheduling are exponential, ranging from enhanced project visualization to real-time project monitoring. These benefits and their effect on construction projects transform digital twin technology as a strategic investment for the construction sector.

Conclusion

On a concluding note, digital twin technology has multiple features that can be employed in maintaining construction schedules. However, it is essential to keep in mind that there is no one way to go about it. Innovatively incorporating novel technology barely comes with an instruction manual. It is all about testing out the tools and features that come with the technology, in ways that best suit your project management needs. It is high time to digitally transform your construction projects to optimize team performance and enhance construction efficiency.