Unleash Your Creativity: How Multi Color 3D Printing Transforms Design

Discover how multi-color 3D printing opens new design possibilities, allowing creators to bring vibrant, complex projects to life with unmatched precision and versatility.

3D printing has revolutionized how we create and innovate, but monochromatic prints sometimes need to be improved. Multi color technology, however, adds a vibrant twist, bringing intricate designs to life in ways we never thought possible. This game-changing innovation is transforming various industries by enhancing design flexibility and reducing the need for post-processing. Whether you're a hobbyist seeking to add flair to your creations or a professional aiming to streamline production, multi color 3D printing offers exciting new possibilities. Let's explore how this technology is reshaping the future of design and manufacturing.

What is Multi Color 3D Printing?

Multi color 3D printing creates objects with several colors simultaneously. This process uses advanced multi color 3D printers equipped with multiple filament extruders, which produce detailed, vibrant models in one go. I once printed a small sculpture with striking hues that my friends believed was painted when it came straight off the printer. In industries like fashion and art, this technology pushes boundaries by simplifying the production of complex visuals.

Impact of Multi Color 3D Printing on Design and Prototyping

Multi color 3D printing revolutionizes design by enhancing creativity and iteration speed. Designers can easily make modifications without traditional constraints. I remember working on a project where a multi color 3D printer allowed me to produce a vibrant prototype overnight, capturing stakeholder attention immediately. Benefits include:

Simplified complex visual testing

Streamlined prototyping process

Enhanced stakeholder presentation

Hobbyists and professionals find this technology offers greater design flexibility and precision.

Why Bambu Lab 3D Printers are Perfect for High-Precision Projects

Bambu Lab 3D printers shine in high-precision projects with unmatched accuracy. I remember printing a detailed architectural model with my multi color 3D printer; its precision impressed my colleagues. Key features include:

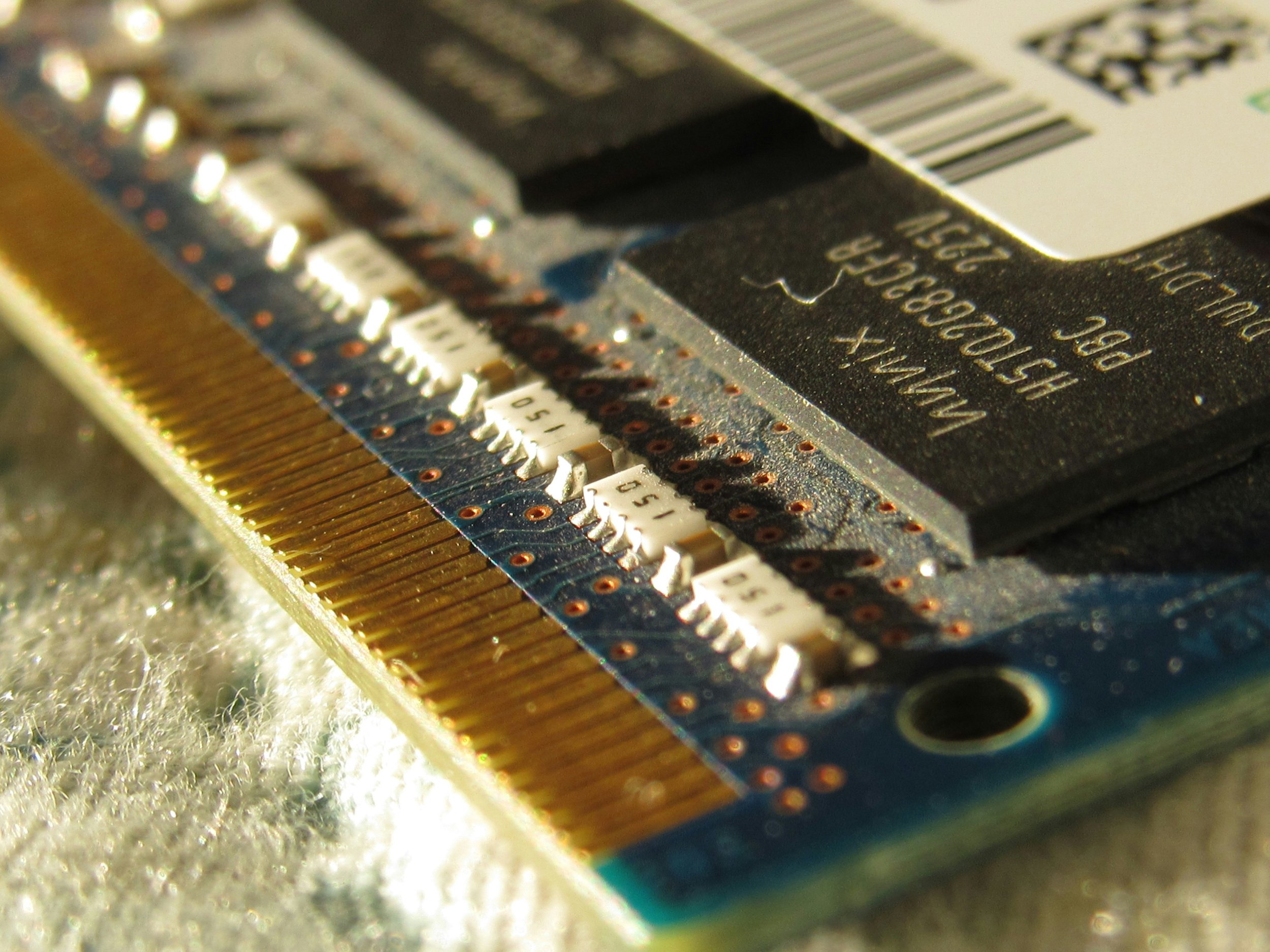

High Resolution: Achieve intricate details with layer thickness options.

Multi-Material Capabilities: Print with various materials without extra effort.

Calibrated Engraving: Use precise engraving features to create fine details.

These features make Bambu Lab printers ideal for precise and complex designs.

Discover the Cutting-Edge Features of Bambu Lab 3D Printers.

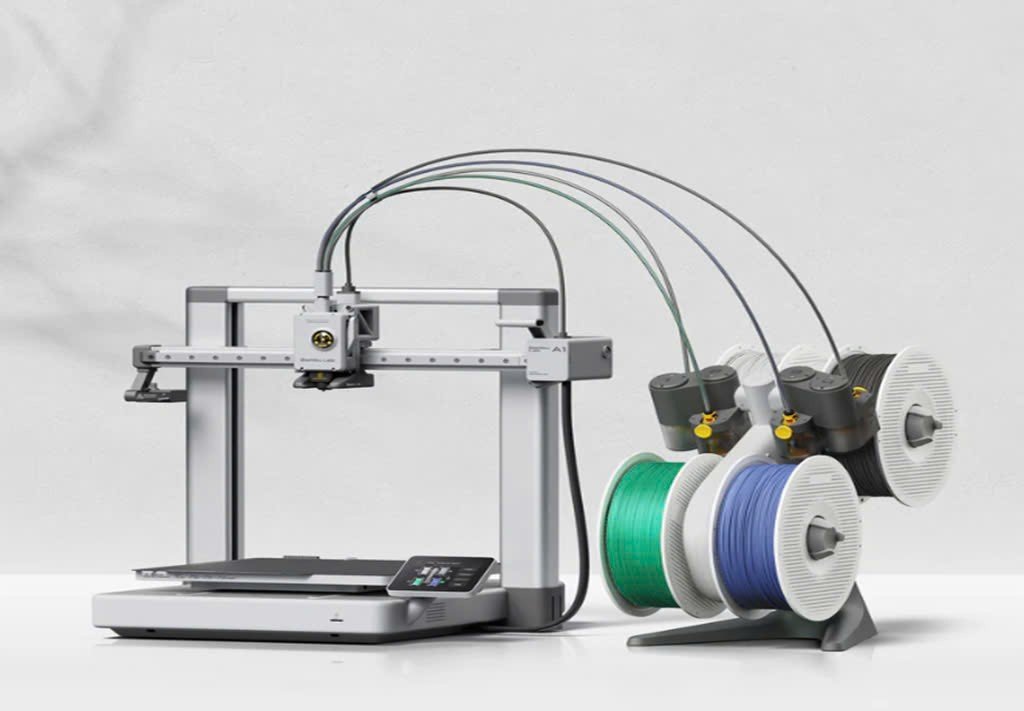

Bambu Lab A1 3D Printer

Bambu Lab A1 3D Printer shines with its full-auto calibration, making it a breeze to start printing without fuss. The multi color printing option in the Combo version sparks creativity by mixing hues effortlessly, and the active flow rate compensation ensures smooth layer consistency. I remember trying the 1-clip quick swap nozzle and loving the ease it brought to changing filaments mid-project. It's equipped with active motor noise canceling, so it doesn't disrupt your peace. It's safe and reliable with a 256x256x256 mm³ build volume and a reinforced heated cable featuring Kevlar.

Bambu Lab P1S 3D Printer

The Bambu Lab P1S gets you started in 15 minutes with no hassle. Priced at $849, it's packed with polished hardware and software. Its enclosed body allows high-temp filament printing, which is essential for demanding projects. Accommodating up to 16 colors with AMS, it's a dream for multi color 3D printer fans. The built-in camera tracks your progress, making remote monitoring a snap. With a mind-blowing acceleration of 20000 mm/s², it prints a bench in just 18 minutes—I've timed it myself and was amazed at its speed and precision.

Bambu Lab A1 mini 3D Printer

Compact yet powerful, the Bambu Lab A1 mini is affordably priced at $349. It boasts full-auto calibration for ease of use. Four-color printing with AMS lite support adds to its versatility. While operating in silent mode, noise stays below 48 dB, perfect for quiet environments. Its full-metal linear rails and bearings guarantee durability. The printer also features vibration and flow rate compensation, making it an ideal choice for beginners and seasoned enthusiasts aiming for precision.

The Benefits and Applications of Multi Color 3D Printing

Improved Design Accuracy

Multi color 3D printers boost design precision by allowing detailed color differentiation, which reduces misinterpretation. This accuracy helps in fields like architecture, where exact hues denote different materials or features. I once used a multi color 3D printer to create a home model with distinct colors for windows and doors, enabling clear visualization for clients. This detail-oriented approach leads to fewer design errors.

Enhanced Prototyping Efficiency

Prototyping gets a speed boost with multi color 3D printing. The process integrates color directly, removing the need for time-consuming post-processing. Rapid iterations mean designers tweak models and get feedback quickly. When I printed a vibrant prototype overnight, stakeholders immediately understood the design's intent, leading to faster decision-making. Streamlined processes like this keep projects moving at a brisk pace.

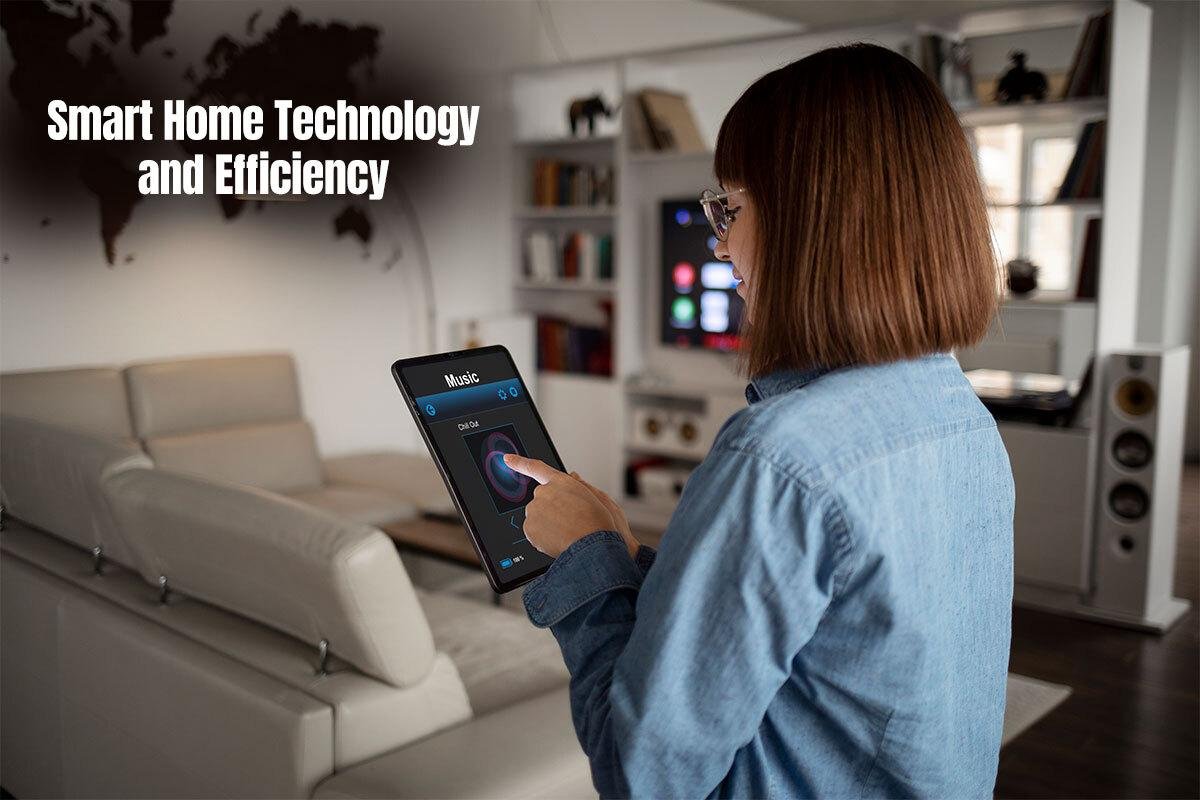

Communication and Collaboration Benefits

Multi color 3D printing aids communication by producing clear, detailed models that stakeholders can easily comprehend. Teams collaborate better when everyone visually interprets the project similarly. Vivid color schemes highlight specific areas that need focus or adjustment. These shared models foster productive discussions, as visual clarity cuts through potential misunderstandings, making adaptations straightforward.

Technologies Used in Multi Color 3D Printing

Modern multi color 3D printers employ technologies like multiple extruders and advanced slicer software. Printers with numerous extruders can handle different colors simultaneously, enhancing print complexity. Slicer software also optimizes layer paths for clean color transitions. These technologies work together to create intricate, multi-part models that require minimal manual finishing, making the entire process more efficient.

Applications in Functional Testing and Marketing

Multi color 3D printing offers a hands-on method to evaluate form, fit, and functionality in functional testing. Designers test the visibility of colored components in real-world scenarios, identifying improvements early. For marketing, vividly colored models attract attention at trade shows and product demonstrations. I recall a product demo where a multi color 3D printed model impressed the audience, effectively conveying our message and piquing interest.

Conclusion

Multi color 3D printers breathe life into creative projects. I remember designing a multi colored prototype that captivated my team's attention with its vibrant clarity, transforming our presentation. This technology rapidly turns ideas into tangible objects, enhancing creativity and communication.

Stay up to date with our latest ideas!

Exclusive deals just for our readers! Click below to unlock special offers and elevate your shopping experience!